Work in progress on new Carignano Kindergarten

Three schools with separate, coloured units, arranged in a comb-like fashion and orientated towards the sun, linked by a group of studios and services. The complex is characterised by a long glass wall, through which you can catch a glimpse of the large rainbow painted on the ground. Innovative technology and tailored fittings transform the building into a workshop where children can learn how to save energy and protect the environment. The building, prefabricated in XLam wood and natural materials and assembled using drywall techniques, will be classified as “near zero energy”, as approximately 1.5 litres of fossil fuels per metre2 per year will be sufficient to provide heating and hot water.

Panoramic view of the ‘Carignano Kindergarten’ Site

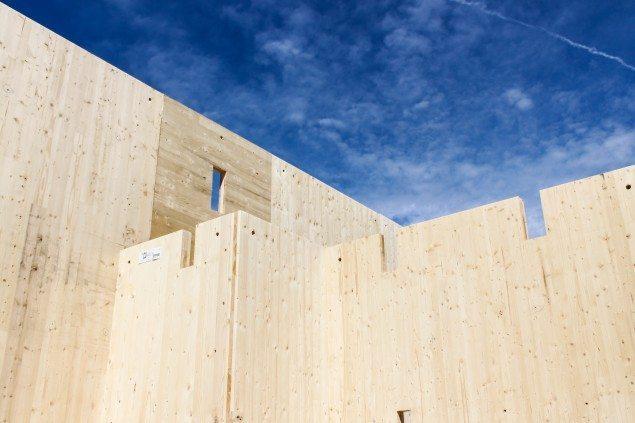

The first load-bearing walls, in XLam cross-laminated glulam wood panels, have been installed!

Installation of the first XLam walls

Progress of Unit A works

Part of XLam Wall with Holes for Trusses and Roofing

Positioning of XLam Walls

Works on Unit A

XLam Walls on Wood Bond Beam with Interposition of Thermal-Acoustic Insulation Membranes

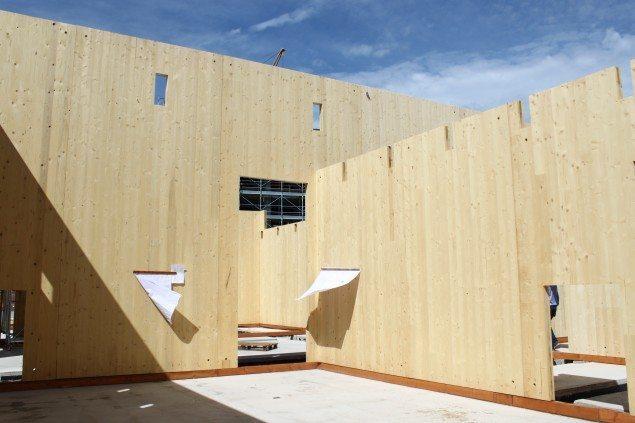

Xlam panels for structure A and structure B’s foundations

While the Corps A growing, preparing foundations with ventilated crawl spaces for ventilation asylum bodies B and C

Preparation of the Foundations with Crawlspace using Air Igloos and Vents

Preparation of elements for wood-to-wood joints

Load-bearing Structure in XLam and Glulam Wood Covering

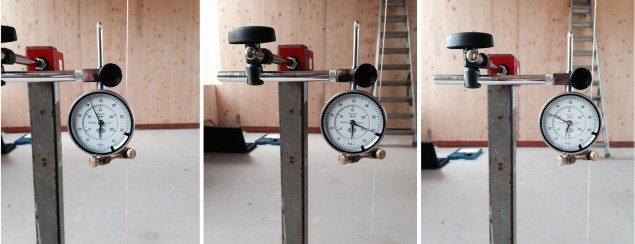

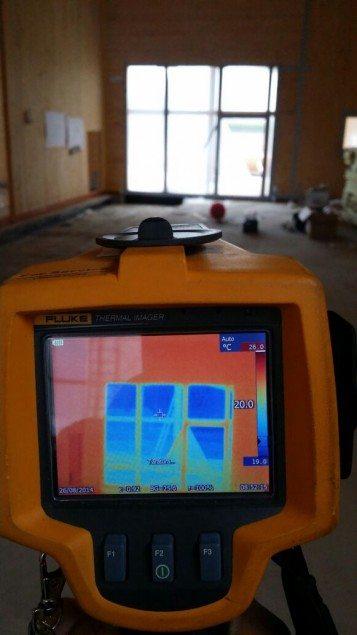

After completing Unit A, we carried out the Blower Door Test, which allows us to check the building’s seal.

This method allows us to identify “air losses” present in the building shell and to evaluate the flow (or rate) of air change. The building passed the test at the first time of asking, with a result of 0.21/h (i.e. 0.21 air changes every hour) and thus comfortably complies with Passive Building requirements (limit of <0.6/h)

[caption id="" align="aligncenter" width="635"] Unit A completed with Blower Door Test[/caption]

Unit A completed with Blower Door Test[/caption]

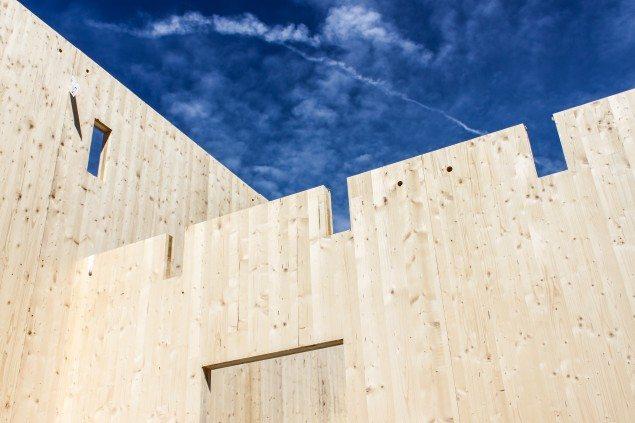

Unit B in progress

XLam Structure for Unit B and Foundations of Unit C

Completion of Unit B

The Blower Door Test was also carried out on Unit B, once the load-bearing structure had been finalised. Using a specially designed ventilator, air is blown into and drawn out of the building. The strength of the ventilator is regulated to adhere to a preset difference between internal and external pressure. The difference in pressure between two sections of atmosphere is the cause of air flows. The ventilator is mounted in a frame, which is then attached to the entrance door, thus earning it the name Blower Door Test.

Instruments that measure the pressure difference and airflow intensity are attached to the ventilator. The rotation speed of the ventilator is regulated so that a specific difference between internal and external pressure is created. As a consequence, an air flow is generated which compensates for “losses” in pressure differences due to seepage. The air flow recorded is divided by the building volume. This figure can then be compared with other buildings and normative standards to gauge the quality of the building’s seal. Given that air seepage corresponds to thermal loads which the heating/air conditioning system of the building must compensate for, the Blower Door Test is crucial for evaluating the thermal-energetic performance of buildings, especially if high energetic efficiency is desired.

The specific calculation process is regulated by norm UNI EN 13829: “Thermal performance of buildings – Determination of air permeability of buildings – Pressurisation method using ventilator”.

Ventilator in Action for Blower Door Test

Blower Door Test Equipment

Unit C under construction

Tests on the building for Blower D

Positioning of XLam Panels for Unit C

Work in progress | Site September 30, 2014

Site | 3 novembre 2014